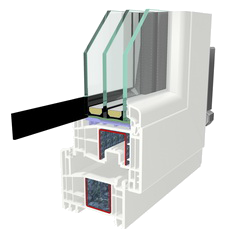

STV® static dry glazing is a new fixation technology for manufacturing windows. The core of the new solution is a new high-performance adhesive strip designed especially for the fenestration industry. The strip is attached to the profile, and is delivered to the manufacturer as a single unit. Assembly and processing can proceed normally without costly investment in new equipment. Cutting, welding, corner cleaning and glazing can be carried out with only minimal changes to the workflow.

STV® static dry glazing is a new fixation technology for manufacturing windows. The core of the new solution is a new high-performance adhesive strip designed especially for the fenestration industry. The strip is attached to the profile, and is delivered to the manufacturer as a single unit. Assembly and processing can proceed normally without costly investment in new equipment. Cutting, welding, corner cleaning and glazing can be carried out with only minimal changes to the workflow.

The combination of STV® technology with conventional steel stiffeners makes it possible to build windows that are larger and better performing than what was possible before. Current window sizes also benefit from the new technology, since alternative stiffeners with thermal breaks can now be used. Even special constructions can be made more stable.

The steel stiffener can also be left out of the finished window for significantly better U-values. Normal sized white windows can now be made without steel bars on the inside with the STV® technique. This leads to a remarkable improvement of up to 0.2 W/m²K in the efficiency rating, depending on the profile system used.

Affixing the pane with the casement stop with STV® technology also improves the security against forced intrusion. The adhesive strip makes it much more difficult to pry out the pane.

STV® static dry glazing can also be used for special constructions, such as round elements. In this case, however, the adhesive tape is applied to each profile section with a hand-held tape dispenser after the bending process and other certain prerequisites. The surface tension of the profile has to be checked with a pin gauge in order to ensure proper bonding between the profile and adhesive tape. If it is not sufficient, a special primer is available that can be applied to the pane and thus improve the quality.

- The advantages of STV®:

- No investment needed - Compared to bonding with liquid adhesives, no additional machinery investment costs are incurred with GEALAN STV® The adhesive tape is pre-applied to the casement overlap during the profile extrusion.

- No change to workflow - The production process remains the same during cutting, fusing, trimming and glazing. Only slight workflow adjustments are required to meet the requirements of static dry glazing.

- Higher insulation - Construction of normal-sized elements can be done completely without conventional steel stiffeners. This can improve U-values by up to 0.2 W/m²K, depending upon the profile.

- Better stability - The combination of STV® with conventional steel stiffeners makes it possible to create larger elements than were previously possible with better functionality. Even special designs can be made more stable.

- Better security - The complete gluing of the pane to the casement improves the secirity, making it even harder to pry out the pane.

- Savings potential - STV® doesn't only save in steel used, but also in reducing the time needed for setup and adjustments. The savings in weight also makes installation easier.

- Certified advantage - All STV® components have been tested according to the RAL regulations for adhesive constructions.